Our Machine Tools

Here you will find an overview of our machine tools, used to meet the needs in industrial sectors such as aerospace, energy, and high-tech. Each machine has been carefully selected to ensure impeccable results and very high precision machining.

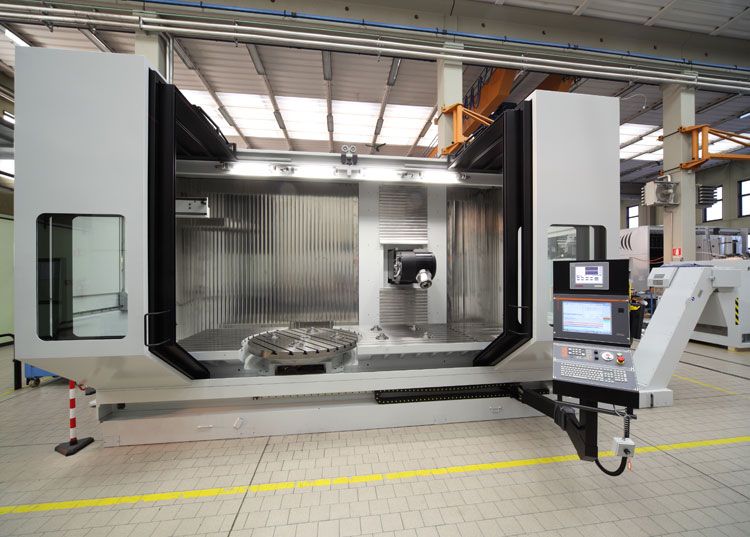

OMV EMERALD 1600 MACHINING CENTER

Technical Characteristics:

Machine type: 5-axis milling machine continue

Rotary table: diameter 1,500 mm, continue

Tool magazine: 90 slots

Types of Machining:

Precision milling, 5-axis machining, large part machining, advanced drilling, roughing and finishing operations, detailed engravings, and complex machining requiring high precision and multiple tool configurations.

MAZAK INTEGREX E500HS CNC LATHE

Technical Characteristics:

Maximum turning diameter: 820 mm

Distance between centers: 1,600 mm

Spindle motor power: 30 kW

Spindle speed: 35 – 3,300 RPM

Tool magazine capacity: 120 positions

X/Y/Z axis travel: 870 mm / 500 mm / 1,589 mm

W axis travel: 1,529 mm

Milling spindle nose: Capto C8

Milling spindle motor power: 37 kW

Milling spindle speed: 35 – 15,000 RPM

CNC: Mazatrol Fusion 640M Pro

Counter Spindle

Continuous 5-axis machining

Types of Machining:

Precision turning, milling, drilling, threading, complex contouring operations, and multi-axis machining.

CNC LATHE HEID S 500 BL

Technical Specifications:

Turning Diameter: 820 mm

Turning Diameter over Cross Slide: 500 mm

X-Axis Travel: 450 mm

Z-Axis Travel: 1,000 mm

Control: SIEMENS SINUMERIK 880 T

Number of Tool Positions: 2 x 12

Spindle Bore: 160 mm

Types of Processes:

Internal Turning, External Turning, Milling, Drilling, Threading, Engraving.

COLOMBO LATHE TPF 1300/1600

Technical Specifications:

Height of centers over bed: 650/800 mm

Displayed

Types of Processes:

External cylindrical turning, Internal cylindrical turning, Conical turning, Facing, Parting off.

PBR TM-30 x 3000 ENGINE LATHE

Technical Specifications:

Center Distance: 3,000 mm

Center Height: 300 mm

Turnable Diameter on Bed: 620 mm

Turnable Diameter on Carriage: 400 mm

Turnable Diameter in Hollow: 860 mm

Hollow Width: 350 mm

Spindle Bore: 105 mm

Displayed

Types of Processes:

External cylindrical turning, Internal cylindrical turning, Conical turning, Facing, Parting off.

PADOVANI LABOR S/200 LATHE

Technical Specifications:

Center Height: 200 mm

Center Distance: 1,500 mm

Turnable Diameter on Bed: 400 mm

Bar Passage: 52 mm

Spindle: Ø 230 mm

Types of Processes:

External cylindrical turning, Internal cylindrical turning, Conical turning, Drilling, Internal and external threading, Facing, Parting off.

SNT TNL120V POWER TURN VERTICAL LATHE

Technical Specifications:

CNC Control: FANUC 18T

Maximum Turning Diameter: 1,650 mm

Maximum Turning Height: 1.000 mm

Spindle Diameter: 1,100 mm

Maximum Load: 4 tonnes

Types of Processes:

Turning of large components, Heavy-duty machining, High precision machining, Milling operations with multi-position turret, Machining complex pieces thanks to advanced CNC programming.

COMEV PICO CM350 SELF-LEARNING LATHE

Technical Specifications:

Maximum Swing over Bed: 700 mm

Maximum Swing over Cross Slide: 480 mm

Distance between Centers: 3,000 mm

Spindle Bore: 110 mm

Center Height over Bed: 350 mm

Types of Processes:

External turning of large diameters, Internal turning, Threading, Deburring, Deep hole drilling.

DECKEL MAHO DMU 70V UNIVERSAL CNC MILLING MACHINE

Technical Specifications:

CNC Control: Heidenhain iTNC 426 PB

X-Axis Travel: 750 mm

Y-Axis Travel: 600 mm

Z-Axis Travel: 520 mm

Table Dimensions: 700 x 500 mm

Maximum Table Load: 350 kg

Number of Tools in Magazine: 16

Spindle Taper: SK40

Maximum Spindle Speed: 14,000 RPM

Types of Processes:

5-axis milling, Precision machining, Complex contouring, Detailed engraving, Drilling and threading, and Grooving operations.

MOVING COLUMN CNC MILLING MACHINE FIL

Technical Specifications:

X-Axis Travel: 3,000 mm

Y-Axis Travel: 1,000 mm

Z-Axis Travel: 1,000 mm

Rotary Table: 1,000 x 1,000 mm

Rotary Head: 2.5° x 2.5°

Types of Processes:

Milling of large components, Moving column machining, Machining on complex surfaces, Precision milling, Drilling on large surfaces, Roughing and finishing operations, Machining requiring rotation of the table and tool for multiple angles.

Uncompromising Precision

At OTARTECH, your challenge becomes our mission. We are here to guide you to the optimal solution, combining our passion for precision with continuous innovation. Contact us today to find out how we can support your project with our customized services.